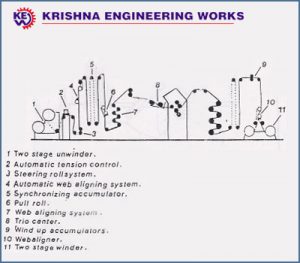

Equipments For Calendering Plant

Calendering Plant

Our company mainly engaged in production of machinery of Calendering Plant. Calendering Plant is designed to shape proper type of material. Generally material is passed through a series of gaps of decreasing size made by a stand of rotating rolls. Each Rollers designed for high quality and accurate thickness per requirement. Rubber sheet thickness determined by final roll gap.

Two Stage Unwinder

Winder with accumulator and edge trimmer, two stage unwinder process uncompromising with flexibility. Two stage unwinder designed for better quality and to improved production reliability with accuracy. Effective Tow Stage Unwinder process with accurate and high production in calendering plant.

Automatic Tension Control

High-precision tension control with quality modular design. It installed where the automatic tension pull roller stands. Featuring and installed before the surface winder for automatic tension control with accuracy. Hydraulic sensor for accurate tension for fabric on calendaring plant, also featuring with optimum spreading effect with highly efficiency of automatic tension.

Steering Roll System

All our rollers designed for accurate and compact steering roll guide system. Rolls are specially designed to work with sensors, also for utilizing an infrared sensor to accurately guide fabric liner at winder and unwinder. Roller system with guiding system and sensors for accurately detect wed edge. Compact and accurate steering roll guide system also, roll guide allows for spreading fabric. Featuring with infrared sensors to guide fabric liner at wind-ups.

Automatic Web Aligner System

Automatic Web Aligner System also called Hydraulic Power Pack units, these are used to automatically guide materials of any width, at any speed, under any load. Completely self-contained with sensors to guide web edge, with an integral air pump. Web Aligner Systems eliminate the need for additional air regulators or plant air. Modular construction and sub plate-mounted components provide maximum ease of servicing. Inherent capabilities of Automatic Web Aligner System with air Pressure Power Units are available in models from 1/4 H.P. to 3 H.P.

Synchronizing Accumulators

Tension controlled accumulators guarantee continuous production regardless for high quality and accurate roller system. Also, it minimize deflection prevents cord accumulation and fabric folding. All Rolls works together for accurate movement of fabric with reducing vibration.

Pull Roll

Entry pull roll stand before the Accumulators are designed to adjust the fabric to next stand. Pull rolls featuring with accurate roller system.

Web Aligner System

Web Aligner System is much more than just an energy source. It’s designed for accurate and high quality edge guiding system. However, because it normally furnishes modulated power to the actuating devices. It’s amplifier of control signals, also power source In addition to providing hydraulic power for the actuating circuit the power unit produces pneumatic power for the sensors. High quality sensor supply pressure must remain constant, and the power supply provides this element. Water, oil and scale contamination and other miscellaneous plant air problems are also avoided.

Trio Canter

The Trio Canter prevents increased cord density at the edges and maintains the exact set width of the fabric. Trio Canter used for Edge guiding and spreading. It’s designed to prevent cord accumulation at the edges of the cord. It works to fabric edges to the set width, left and right.

Wind up accumulators

Accurate accumulation process for Wind-up accumulators, and high quality universal spreader at accumulators. It minimized roller deflection prevents cord accumulation and fabric folding.

Web Aligner

Web Aligner with unique design, which gives extremely narrow dead band & fastest possible response for unexcelled guiding results. Web Aligner available in different models from 0.25 HP to 3 HP to meet any guiding application you may have.

Two Stage Winder

Two Stage Winder designed for accurate and high quality wind up system. Roll system is designed to work together for fabric edge guiding system.